My diy bleeding stand So this was how they came off the car, one had lost a lot of its oil and was it a bit of a sorry state

So this was how they came off the car, one had lost a lot of its oil and was it a bit of a sorry state

Very rusty

Very rusty  De pinning

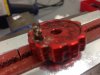

De pinning Shiny and new

Shiny and new I was a bit concerned about getting them apart without damaging anything bit it turned out OK. Bit of warmth from a heat gun and the loctite gave in.

I was a bit concerned about getting them apart without damaging anything bit it turned out OK. Bit of warmth from a heat gun and the loctite gave in.

So this was how they came off the car, one had lost a lot of its oil and was it a bit of a sorry state

So this was how they came off the car, one had lost a lot of its oil and was it a bit of a sorry state

Very rusty

Very rusty  De pinning

De pinning Shiny and new

Shiny and new I was a bit concerned about getting them apart without damaging anything bit it turned out OK. Bit of warmth from a heat gun and the loctite gave in.

I was a bit concerned about getting them apart without damaging anything bit it turned out OK. Bit of warmth from a heat gun and the loctite gave in.